ITP presents the new generation of rice packaging

Rice packaging enters a new era thanks to the innovative film created by our cutting-edge extrusion plant with Triple Bubble® technology

ITP recently inaugurated the new Triple Bubble® line, an innovative production system, unique in Italy, for thinner, lighter and more sustainable films, as they have a reduced carbon footprint.

The R&D team has developed Triflex Risi, a flexible co-extruded film particularly suitable for vacuum packaging rice.

The advantages of the new ITP film for rice

25% reduced thickness

The ITP film is ultra-thin, whilst maintaining unchanged mechanical and optical properties. In this way we reduce the release of plastic onto the market.

Coextruded monofilm

By replacing the coupled film with the new co-extruded Triflex Risi film, a thinner and lighter film is obtained, therefore the environmental contribution is also reduced.

No use of glues

The Triple Bubble® line allows to produce 13-layer films using any type of polymers, avoiding glues for greater food safety.

Less warehouse space required

The 25% reduction in thickness also brings benefits in logistical terms, thanks to the reduction in overall dimensions.

Reduction of machine downtime

For the same size, these reels hold 25% more product, reducing interruptions to replace them.

Savings on transportation costs

Lighter packaging guarantees a reduction in shipping costs and emissions of polluting gases.

Vacuum packaging of rice

In order to best preserve the organoleptic characteristics of rice, also protecting it from contamination by external agents, vacuum packaging represents an optimal choice.

In particular, the new film boasts a barrier that prevents the passage of MOSH (Mineral Oil Saturated Hydrocarbon) and MOAH (Mineral Oil Aromatic Hydrocarbon), mineral oils of fossil origin which are harmful to health and which migrate from recycled cardboard packaging to the film and, in the absence of a barrier, they attach to foods.

The absence of contact with air allows a significantly extended shelf-life of the product, thus combating the scourge of food waste.

The technologies traditionally used for the production of bags for vacuum packaging of rice involve lamination, that is, the coupling of different types of film:

- OPA/PE

- CPA/PE

These packages are very thick and therefore heavy, as they are made up of multiple layers.

Triflex Risi: the thin film for rice by ITP

The innovation introduced by ITP instead allows for a co-extruded film for vacuum packaging of rice. This results in a much lighter package (-25%) while maintaining the fundamental characteristics for this type of product unchanged:

- High barrier for water

- Medium barrier for oxygen

- Barrier for MOSH and MOAH

- Suitable for VFFS packaging

- Puncture resistance

- Weldability

- Printability

- Rigidity

- Planarity

The reduction in weight implies a proportional reduction in the amount of the environmental contribution due.

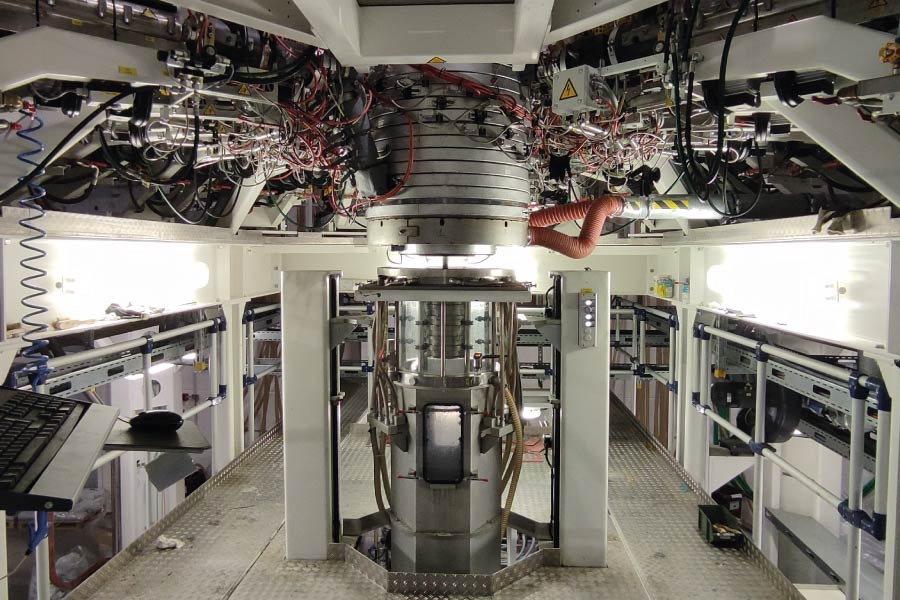

The Triple Bubble® extrusion system

- Fully automated workflow (4.0): all machine parameters are recorded for SMEA/SMED traceability and analysis

- Thickness gauges for consistent film quality

- High cooling capacity for greater film transparency

Triple Bubble® technology for the production of bi-oriented blown films takes its name from the serial arrangement of three bubbles. In the first, the film is rapidly cooled using a technology that exploits cold water, effectively preventing crystallization as a prerequisite for uniform stretching in the subsequent second phase, when the high orientation achieved at the molecular level improves the mechanical and barrier properties of the films . Thermal relaxation in the third bubble serves to set the desired thermoforming behavior.

The production line installed by ITP – 20 m high by 30 m wide – allows the production of films with width from 200 to 900 mm and thicknesses between 20 and 130μm.

The reduction of the film thickness leads to lower consumption of materials and therefore the reduction of the carbon footprint. In downstream processing, storage space is also reduced. Given the lower weight, the environmental contribution also decreases compared to traditional film.

Vacuum packaging, which extends the shelf life for the transport and storage of cured meats, meat, cheese and rice, is one of the typical applications of the film produced with this technology, which combines high transparency with good thermoformability and a high resistance to puncture.